The smart Trick of Motorcycle Parts New Zealand Specialists That Nobody is Talking About

Table of ContentsFascination About Motorcycle Parts New Zealand SpecialistsThe 2-Minute Rule for Motorcycle Parts New Zealand SpecialistsThe Ultimate Guide To Motorcycle Parts New Zealand SpecialistsA Biased View of Motorcycle Parts New Zealand SpecialistsThe Best Strategy To Use For Motorcycle Parts New Zealand SpecialistsThe Of Motorcycle Parts New Zealand SpecialistsNot known Incorrect Statements About Motorcycle Parts New Zealand Specialists The Facts About Motorcycle Parts New Zealand Specialists Uncovered

Reach out to one of our professionals today.CNC machining modern technology is swiftly ending up being the focal point of various manufacturing processes around the globe as a straight result of its several benefits over various other techniques. In addition, the markets that manufacture bikes have gotten on board with this trend. The most cutting-edge firms are now creating their engine components and wheels using machining strategies originally established for motorcycle parts.

You might be wondering why we use. Now that we have your interest allow us clarify the reasoning behind this modern development in the bike production sector.

The Only Guide for Motorcycle Parts New Zealand Specialists

Additionally, you have total control over the appearance of the components, also down to the minute information. Occasionally, motorcyclists may decide to fix up their adventure by installing aftermarket components or customizing the bike's transformation. As soon as again, computer mathematical control (CNC) machining is the most useful approach. Upgrades may be of any type of type and design you desire.

What Does Motorcycle Parts New Zealand Specialists Do?

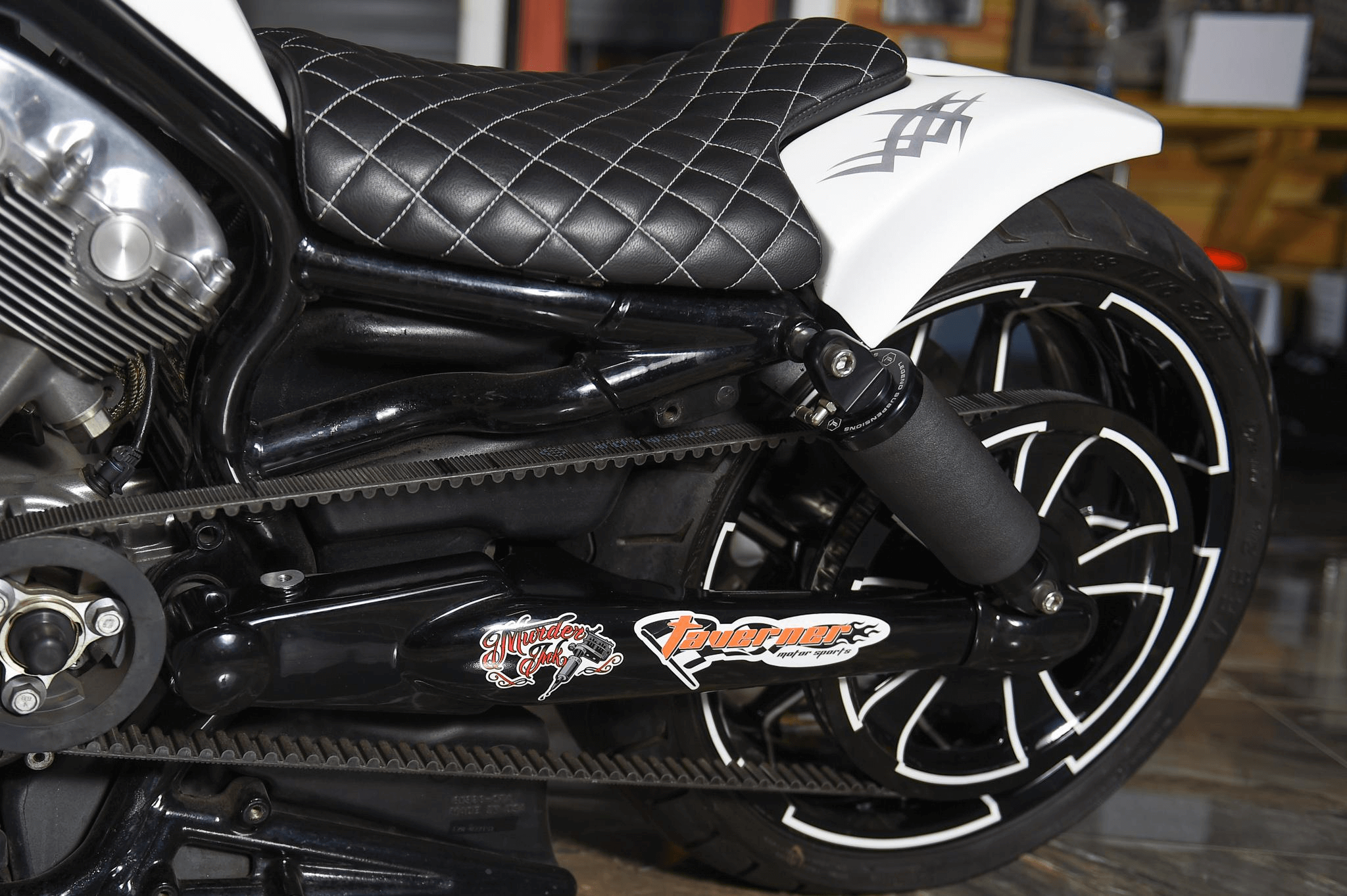

CNC machining may be made use of to make nearly all of a bike's metal and plastic parts. To continue, we'll review several machined components for motorcycles. As opposed to those on cars, wheels on bikes have a tendency to be a lot more obvious. As an outcome, the bike's looks might be improved with the suitable personalization of these wheels.

When personalizing the wheels, the disks are where the emphasis should be. Most of them are made out of aluminum. Aluminum alloys are widely known for the impressive machining capabilities that they possess. Milling procedures are used to acquire the desired degree of wheel customization. Another aspect of the bike that may be personalized is the tires.

The smart Trick of Motorcycle Parts New Zealand Specialists That Nobody is Talking About

When it pertains to a vehicle (or a motorcycle), one of the most crucial component is the engine. A number of individuals point to it as the "heart" of the auto. On the various other hand, the camshaft, the cyndrical tube head, and the pistons often tend to be intricate and call for designs with a high degree of accuracy.

Illumination is an additional complicated aspect of personalization. Usage only top quality products, however, since these lights are critical for the safety of motorcyclists and other drivers or people when driving, especially in the evening. Bike headlights have three major parts: the bulb, or light, the lens, and the real estate. Specifically, we customize the lens and the real estate.

Milling processes with a perfect finish would certainly lead to the lenses having a reflective high quality that is comparable to that of a mirror. The cover, on the various other hand, is not made up of vulnerable products; rather, it is built out of hard polymers that can be machined right into more intricate patterns.

How Motorcycle Parts New Zealand Specialists can Save You Time, Stress, and Money.

Motorbike producers often cast these parts, yet only for the manufacturing of bespoke parts. Machining on 5 axes in today's world is the ways by which any type of design form may be realized.

Select Runsom for your customized motorbike components! We have the capacity to make complex recommended you read and stylish parts making your motorcycle unparalleled.

Below are a few examples of steels typically used in motorbike element machining. Aluminum is the main product made use of by companies focusing on generating personalized motorbike elements to develop the majority of these parts. In the past, we would develop our engines out of cast iron. On the other hand, light weight aluminum is rapidly coming to be the material of choice, partly because of the truth that it is much more light-weight.

Zinc describes an additional metal that is very light go in weight and has fantastic machining qualities due to its high mechanical strength. This product might be created right into nearly any type of form and preserves its dimensions well. Also mission-critical parts that require a high level of precision might take advantage of their use.

More About Motorcycle Parts New Zealand Specialists

One more steel that sees heavy usage in the manufacturing of CNC-customized components is magnesium. It is among the lightest steels that are now easily accessible and has superb machinability functions and stamina compatible with its low weight. Among the drawbacks of magnesium is that its dirt may easily capture fire.

Their most typical usage in creating numerous motorcycle elements is bolts, such as screws and bolts. Their reduced vulnerability to oxidation and rust makes them perfect for this use.

The Basic Principles Of Motorcycle Parts New Zealand Specialists

It appears that CNC turning and milling are the fundamental processes. In addition, it requires maintaining bars of material, most often plastic or metal, in placement and then turning a reducing tool to remove sections of the product as the material is transformed.

These approaches are similarly crucial and produce components with high precision and constant high quality. The processes assist enhance the overall high quality of the machined bike parts.

Facts About Motorcycle Parts New Zealand Specialists Revealed